Description

What is our Recommended Kit?

The idea of offering a Recommended Kit is due to popular requests from the community. Our engineering team has carefully selected the best combination of parts that balances cost and performance. You can rest assured that this kit is very capable of outperforming many others available in the market.

1000x1500 Mechanical Kit

The mechanical kit is the foundation of your CNC Machine. A mechanical kit includes all the mechanical components needed to build your CNC Machine such as extrusions, screws, nuts, washers, bearings, plates, etc.

This mechanical kit can be paired with many different applications, such as CNC Router, Laser Engraving, Plasma Cutting, Plotter, Pick and Place Machines and many other applications that require 3-Axis motion.

| Approximate Cutting Area (mm) |

| X-AXIS | Y-AXIS | Z-AXIS (With 12mm Spoilerboard) | Machine Footprint (Not Including Motors |

| 800 | 1320 |

110 | 1000 x 1500 |

1. X-Axis Features (INCLUDED)

With a length of 1000mm and approximated travel of 800mm, the X-Axis is suspended by Y-Plates on each end. In a CNC machine, the X-Axis is responsible for moving the CNC machine from left to right.

The X-Axis uses a Lead Screw as its transmission System to achieve high-resolution and great repeatability. Our Maker Store C-Beam upgrade called C-Beam HEAVY also features this axis adding strength and beneficiating the machine performance.

2. Y-Axis Features (INCLUDED)

With a length of 1500mm and approximated travel of 1320mm, the Y-Axis is responsible for moving the CNC machine from back to front.

The Y-Axis also uses a Lead Screw as its transmission System to achieve high-resolution and great repeatability.

3. Motion Control (INCLUDED)

The xPRO V5 outperforms all other motion control systems in its class boasting features including an easy plug-and-play connection system, high-quality German 6A stepper drivers, and a 32-bit processor with more than 4x the processing power of other Arduino (ATmega) based controllers.

This motion control we have put together in this kit also pairs the xPRO with a compatible and reliable power supply, cables, emergency stop button and limit switches.

4. Cable Management (INCLUDED)

When wiring up a CNC Machine, even a simple CNC machine, there will be a lot of cable runs that are needed for all the components of the electronic system. These cables will quickly start getting in the way of moving parts and if there is no cable management there is a serious risk of damaging cables which can be extremely unsafe when the CNC machine is operating. That is why we have put together this Cable Management System in our recommendations.

5. High Torque Motors (INCLUDED)

Stepper Motors also will define how hard your machine will move through the material. The Maker Store High Torque Motors ensure that your machine responds to the friction caused by the material confronting the workpiece.

6. Touch Probe (INCLUDED)

The Touch Probe is designed so that it will sit off the corner of the workpiece allowing you to position the X and Y zero coordinates as well as the Z zero coordinate accurately and easily.

7. Spindle/Router Bracket (OPTIONAL)

The Spindle/Router Bracket is responsible to attach your Spindle or Router to your Mechanical Kit. You can either use one of two pieces to secure your Spindle or Router.

We recommend that you measure the outer diameter of your Spindle or Router to select the correct Bracket size.

For example, a Makita Router RT0700CX has a body diameter of 65mm, you should then select the 65mm bracket.

8. Not Included

- Machine Assembly Service

- Spindle or Router

- End Mills or Collets

- Computer

- Paid Software

- Any Mains wires

- Spoilerboard/Wasteboard

About the WorkBee V3

The WorkBee CNC Machine was originally designed by Ryan Lock of Ooznest UK. It is a strong, accurate and easy assemble CNC machine. This WorkBee V3 is the Maker Hardware kit based on the popular WorkBee CNC Machine design. The Maker Hardware WorkBee V3 CNC is an upgrade to our WorkBee V2.2.

This new Version 3 model is heavily modified to achieve better results. It is important to note that the new upgrade is VERY different to the Ooznest or other manufacturer's models. The Maker Hardware WorkBee V3 has two interchangeable transmission systems allowing for a high level of customisation as well as axis compatibility with up to 3m in length, allowing for full timber sheets to be worked on!

The WorkBee V3 CNC Machine is a 4-axis (3 + 1) machine, this means there are 3 physical axes (X, Y, Z) and a slave axis of Y which is called the A-Axis.

This is a perfect CNC router Machine for the hobby woodworker who wants to get into CNC woodworking. The WorkBee V3 is easily customised and adaptable, all parts of the machine are generic and modular encouraging additions and alterations after the initial mechanical build.

The WorkBee is our most customisable CNC machine and can be supplied in almost any size imaginable. If the application requires a cutting area larger than 1500mm the WorkBee V3 is our solution.

Main Upgrades From Previous Versions

While there are so many different features, below are some of the Key Features that are new on the WorkBee V3.

Strong M8 Hardware On Weight Bearing Wheels

|

The top rows of wheels on both the Y-Axis and the X-Axis have been upgraded to use M8 Bolts and larger bearings inside the wheels. By upgrading the top rows of wheels from M5 hardware to M8 hardware a stronger axle is created. This is a great and effective improvement to increase the rigidity of the assembly while also reducing 'flex' in the assembly. |

Z-Axis with MGN 15 Rails and Bearings

|

MGN Rails are a low-profile version of the well-known HGR rails. The New Z-Axis uses High-Quality MGN Series Linear Rails and MGN15C Bearings. This combination of rail and bearings offers high rigidity and precision accuracy in linear motion. Used in 3d Printing, CNC Machining, Robotics, Measuring Equipment and linear motion actuators. The WorkBee V3 takes advantage of the low-profile MGN rails that are responsible for keeping the centre of gravity as close as possible to the X-Axis gantry. This simple "trick" mitigates the X-Axis from twisting and causes less stress on the Y-Axis wheels. |

Cap Head Screws - Also known as Socket Head Screws

|

The WorkBee V3 has upgraded any screw that does not need to have the Low Profile Head to the Stronger Cap Head Screw. This simple upgrade makes the assembly of the machine much easier as it minimises the risk of stripping the head of the screw. |

|

|

Jaw Couplings have been used to connect all Stepper Motors to Lead Screws. Jaw Couplings are stronger and longer-lasting by design when compared to their Flexible Coupling cousins. Jaw Couplings are more precise in acceleration and deceleration. Jaw Couplings have less backlash than Flexible Couplings. |

Lead Screw Tensioning Nut

| The WorkBee V3 has upgraded the outer locking collars that hold tension on the lead screw to the new Lead Screw Tensioning Nuts. This specially designed nut when installing a Lead Screw in tension helps reduce Lead Screw ‘whip’ which occurs in Lead Screws with lengths greater than 1000mm. Installing the nut onto a Lead Screw helps ensure your machine runs smoothly at higher feed rates. |

|

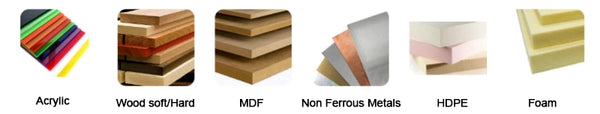

WorkBee V3 Material Capabilities

WorkBee V3 was designed to drive your Router/Spindle consistently through different materials.

CREDITS:

The New Maker Hardware WorkBee V3 is substantially different to all other WorkBee models as well as the predecessors before it. The machine was inspired by the Lead CNC, the Ox-GEAR, and the earlier WorkBee models. Without these previous machines that came before the WorkBee V3, the machine would not be possible.

- The WorkBee V3 Pates were designed by Maker Store Australia. This design allowed for a gear rack and pinion transmission system on the X-Axis and Y-Axis.

- The Internal MOD 1.0 Gear Rack was designed by Maker Store Australia

- Ox-GEAR CNC and Ox V4 CNC were designed by Maker Store Australia

- C-Beam HEAVY was designed by Maker Store Australia

- Ox V1 (belt) was designed by OpenBuilds USA

- C-Beam was designed by OpenBuilds USA

- WorkBee V1 was originally designed by Ooznest UK

Please note the Maker Store WorkBee V3 is heavily customised and upgraded to the original design by Ooznest. WorkBee V3 is different to all other company's "WorkBee Variants".

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.